Zipped!

Unzipped!

I absolutely love my velvet bomber jacket. I have worn it almost constantly since I finished it, with jeans, joggers, turtlenecks, you name it. I've worn it "out", to the market, and everywhere else. It is so versatile and so warm. There were times I thought I would throw it across the room and never look back but I am so glad my persistence won out, once again. I just can't walk away from a project. There is ALWAYS a way thru!

Pattern:

Bomber jackets seem to be all the rage right now but truthfully, they have always been in fashion. This design was usually seen on the testosterone filled side of the runway but like much in fashion, today it is universal in regards to gender. Yay, for that! It's comfort and versatility are certainly to be enjoyed by all. Being sewists, we can make our bombers out of any fabric we want, a great opportunity for expression! I had a specific vision in mind and took to Google images for more inspo. What I found were two versions, one being just what I wanted, a shorter, fuller, version with a more defined waist. Most versions, and this definitely applied to patterns, were cut stright down from the chest to the hips, had no shape definition other than being rather closely fit, like this.

What I had in mind was more of an "urban" look. These were fuller sleeves that were either dropped or raglan and ribbed hems that were closer to the waist, more like this:

I apologize in advance if the images disappear from their vendor sites. I searched patterns all over and could not find what I wanted. I settled on Vogue 1877. a unisex pattern, and did adjustments to achieve my look. Of course, half way through my jacket sewing, I happened on the perfect pattern, so I offer it here for you if you like this look: TCP4 The Bomber Jacket from Trend Patterns. I found it with a search on The Fold Line.

Fabric:

This was the interesting part! I've been doing a lot of reorganizing of my fabrics lately, mostly because of those labels I purchased that let me write down the yardage and other info on each piece of fabric I own. I have some really lovely pieces, some for a life I rarely live. I bought this beautiful cotton/rayon velvet online a few years ago with intentions of making a blazer type jacket for the holidays. My blazer days seem to be gone. If I made it, it would probably be a one and done. Lately, fashion changes have given me permission to use more formal fabrics for more casual clothing. As I measured out this piece for its label, it occurred to me that I could make a bomber jacket with it and could get a lot more wear out of it and it would be beautiful. I proceeded!

The outer shell is a cotton/rayon velveteen. It has been machine washed and dried, no shrinkage and looks fine and lush. Washing velvets is something I have subscribed to for a long time. It makes them practical and changes their hand to a deep lushness. Don't believe me? Wash a good sized sample on warm and dry. You'll see.

I needed warmth and was not going to rely on just the velvet for that. This was a transition piece for 30 to 50 degree weather. It has worked out beautifully, very warm. It is lined with my favorite Kasha, a flannel backed Satin, perfectly luxe and warm.

The rib knit was my issue. I am not experienced with rib knit other than on a long tee shirt or two. I've only used what I picked up at Joann's. I went to Etsy for nicer, heavier offerings and ordered what was for jackets, "great for varsity jackets". Sounded good. It came in and damx, it was thick but I figure this was what I was supposed to use and proceeded. One of the first things to do on this jacket is install the zipper. Between the zipper, the rib knit collar layers, the Kasha layers and the velvet layers, this was incredibly bulky to sew. I pressed my velvet and clapped it down!!! A stiff brush brought the nap back up pretty easily, which I owe to the prewashing. It was just a very unpleasant experience all the way through, sewing all those heavy layers felt like stitching a rubber tire. I had to do a lot of the finishing by hand and that stunk as well. I was not excited to work on this so it happened in bits and pieces while I worked on alterations for customers in between to keep my sanity. Once done, I tried it on and was sooooo very happy. It was worth the aggravation. Then I wore it out on a 45 degree day and was overjoyed, wore it with jeans and a turtle to the supermarket. It felt so warm and nice. Persistence won the game once again.

Construction:

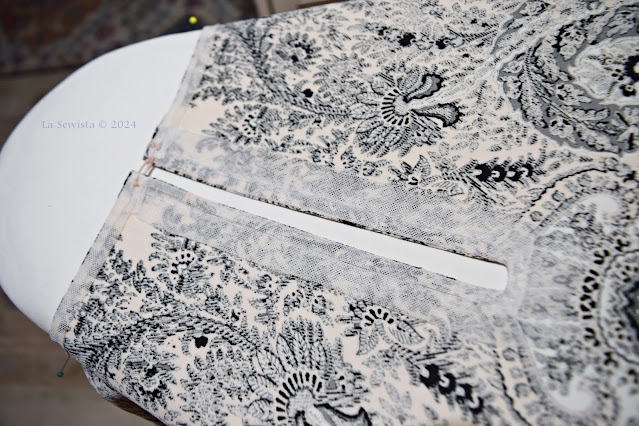

First there was the zipper. A facing of the velvet was attached to the Kasha lining. The coil zip was in between the outer velvet and the the velvet facing. At the very top it met the corner of the rib knit collar. I set the collar back about a half inch and was glad I did. It gave the end of the zip a little extra space for all the bulk involved there.

This pattern had two collars, one a big camp collar and the other a high stand up collar. I wanted a real rib knit bomber collar. No pattern! I pinch hit and it came out OK. I just folded the rib knit and cut out a crescent. Fingers were crossed and whew,,, it worked. Every seam was bulky. The next thing that was a bother were the shoulder seams, a definite pattern issue. I have seen this on more patterns, both indie and the big guys. The pattern gives you a clear dropped shoulder. Then it has you attach a sleeve with easing. There is no bump, lump or bone for the fabric to go over where these seams meet and therefore no need for ease. Well, you've got it and you are left with unsightly easing puffs in the middle of your bicep. I steamed the bejeepers out of this seam to rid the sleeve of this easing puffiness which would have been fine if the sleeve had to go over a shoulder bone. Someone behind a computer, at some point, stuck a regular sleeve on a dropped shoulder, never having the knowledge that no enlargement would be needed as the sleeve draped straight down the bicep. Trust me. Take a look at dropped shoulder patterns. You will see this mess everywhere. Check any dropped shoulder patterns you do so you can eliminate the extra before sewing this area. Luckily, my velvet took the abuse well, as you can see above.

The jacket had welt pockets. While I like welt pockets, these are uncomfortable to use. They are set too high and in just a weird spot. Having looked at other such pockets in my research, they were also set in the same weird spot. They don't look bad. They just feel bad. You can't lower them because the pocket bags have no place to go. Nature of the beast, I guess. They are pretty, though. It had been a while since I had done welt pockets so I watched a lot of vids and did many samples before committing. If you do a mockup for your bomber jacket, make a pocket, just one, and make sure you like it. If you don't, just do a faux pocket, a lot less work. Also, just look closely at the pockets in the pics above and you will see what I mean.

Fit:

Lately, in my body changing journey, my shoulders have started to slope down. This jacket really emphasized that. I added 1/2 inch raglan shoulder pads and it GREATLY inproved the fit. These are tools that are out there for you to use, not just laughable objects from another era. This pattern specified a lot of topstitching. I did the yoke first and did not care for the look. I did not do any more.

I reduced the length of the jacket by 2.5 inches. I tightened up the rib knit hem band by to be closer to my natural waist rather than hip size. To make the jacket bottom fit the smaller band, I did tucks in the back and front. It was all too heavy for gathering. It worked out fine but added even more bulk for sewing in those areas. I shortened them an inch but kept the fullness in the sleeves as I saw that fullness a lot in the versions I liked. See the brown jacket above. There is a lot of ease in this pattern as I have often found in unisex patterns. I kept it and did no FBA or petiting.

In Conclusion:

I love this jacket and foresee getting a lot of wear from it. All parts have withstood my prewashing so I can see it giving me years of joy and warmth. It is so comfortable and warm and just perfect for when our temperatures are not brutally winter but still chilly. It can also be casual or dressy. I love it and highly recommend the pattern as well as being a little daring and making it up in a bold fabric, perhaps a brocade or velveteen or how about a beautiful organza? I hope this inspires you. Happy Sewing........Bunny